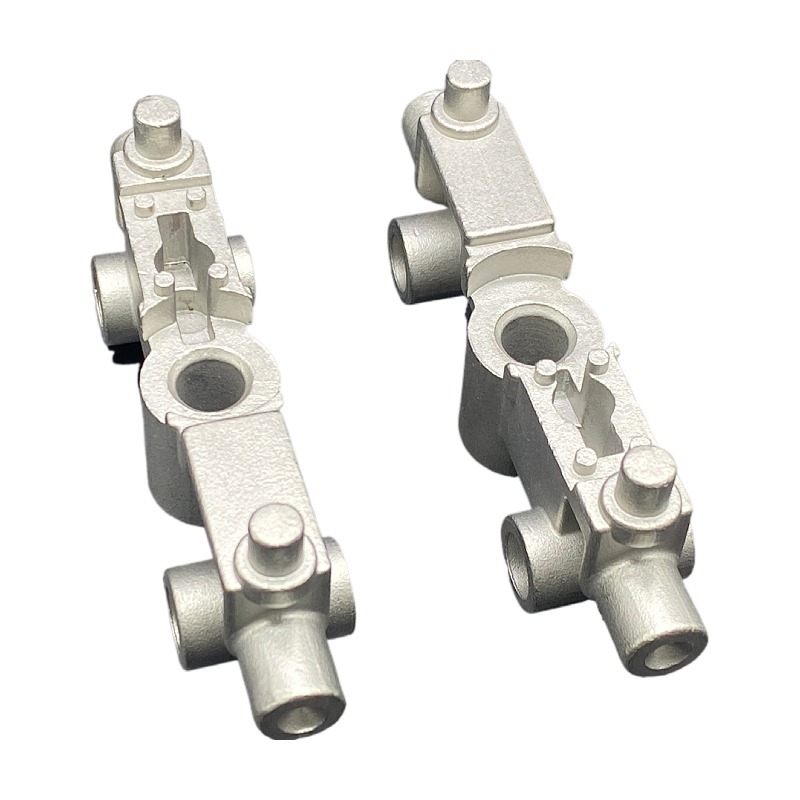

Custom Cast Part

Custom metal parts casting. Inquiries can be sent online now.

1. We will respond to inquiries within 24 hours.

2. Send casting solutions for free.

3. High quality custom production.

4. Fast global delivery.

Custom cast parts

Professional metal casting factory, with advanced equipment and technical team, tailor-made design and processing solutions for you to meet your individual needs.

Casting is a manufacturing process where molten material is poured into molds to create specific shapes and forms. Common casting materials include metals like aluminum, iron, and bronze. This versatile technique is utilized in various industries, including automotive, aerospace, construction, and art. Products range from engine components and machine parts to decorative sculptures and intricate industrial fixtures, making casting essential for producing both functional and artistic items.

Cast Part

Professional custom cast parts, complex shapes, various materials, or high precision requirements, custom parts we can meet.

Ability to Process Materials

Aluminum

Properties: Lightweight, excellent corrosion resistance, good thermal and electrical conductivity.

Applications: Widely used in automotive parts (engine blocks, wheels), aerospace components, consumer electronics, and household items.

Steel

Carbon Steel: Good strength and ductility; used in a variety of structural applications.

Alloy Steel: Contains additional elements to improve specific properties, used in automotive and industrial applications.

Applications: Heavy machinery, construction materials, and tool manufacturing.

Iron

Gray Iron: Contains graphite flakes, providing excellent castability and good wear resistance; used in engine blocks and pipes. Ductile Iron: Contains spherical graphite, offering higher strength and ductility; used in automotive components and machinery parts. White Iron: Hard and brittle, often used in wear-resistant applications. Applications: Structural components, machinery, automotive parts.

Copper

Properties: Excellent conductivity and corrosion resistance; often alloyed with other metals.

Applications: Electrical components, plumbing fixtures, and artistic applications.

Bronze

Properties: Alloys of copper, tin, and sometimes other elements like aluminum or phosphorus; known for good corrosion resistance and wear resistance.

Applications: Marine applications, bearings, valves, and sculptures.

Efficient and accurate casting services to help you achieve project success

Surface finishing

Cleaning

Purpose: Remove impurities, oils, and residues.

Methods: Mechanical cleaning (abrasive pads, brushes) and chemical cleaning (solvents, acids).

Deburring

Purpose: Smooth sharp edges and remove burrs.

Methods: Manual scraping, tumbling, or using specialized machines.

Surface Coating

Paints and Primers: Provide corrosion resistance and aesthetic finishes. Powder Coating: Durable finish applied electrostatically and cured. Galvanizing: Zinc coating for corrosion protection.

Plating

Purpose: Apply thin metal layers (e.g., nickel, chrome) for enhanced corrosion resistance and appearance.

Applications: Used in automotive parts and decorative items.

Heat Treatment

Purpose: Alter mechanical properties like hardness and strength.

Processes:Annealing: Relieves internal stresses. Quenching and Tempering: Achieves desired hardness.

Passivation

Purpose: Improve corrosion resistance, especially in stainless steel.

Method: Acid treatment to create a protective oxide layer.

Shot Peening

Purpose: Enhance fatigue resistance by inducing compressive stresses.

Method: Blasting small metal shots onto the surface.

Surface Hardening

Purpose: Increase wear resistance and surface hardness.

Methods: Carburizing: Infusing carbon into the surface. Nitriding: Adding nitrogen for enhanced hardness.

Polishing and Buffing

Purpose: Achieve a smooth, shiny finish for aesthetics.

Method: Using abrasives and polishing compounds.

Specialized Coatings

Purpose: Provide protection based on environmental conditions.

Examples: High-temperature ceramic coatings or chemical-resistant coatings.

Why customers choose us

Customized services

Fast delivery time

High quality finished products

We specialize in casting parts services, according to the needs of customers to develop appropriate processing solutions. Our team of professionals will work closely with our customers to ensure that the final product meets their design and specifications.

We focus on time efficiency and strive to complete customers’ orders within a reasonable time. We have efficient production processes and teams to ensure timely delivery of our customers’ parts and meet their needs for fast delivery.

We provide high quality casting services to ensure the accuracy, quality and durability of parts. We use advanced machines and processes to ensure that every part meets customer requirements and specifications.

Competitive prices

We offer competitive prices while maintaining high quality processing services. We focus on cost control and efficiency improvement to ensure that our prices are satisfactory to our customers.

Reputation & reputation

We have a good reputation and reputation, and have established long-term cooperative relations with many customers. Our customers are very satisfied with our machining services and are willing to recommend us to other customers.

Perfect after-sales service

We provide perfect after-sales service to ensure that customers in the use of our products in the process of any problems can be solved and supported in a timely manner.

Contact us

Professional CNC machining, casting, forging & die casting Manufacturer

1. When did your company start casting business?

We started casting business in 2009.

2.Can you customize the processing service?

We specialize in custom casting and machining services.

3.What does the quote require?

Quotes require 3D model data files or drawings or existing samples and production quantities.

4.What kind of material can you make for casting custom parts?

Steel, Brass, Copper, Iron, Bronze.